The manufacturing process can be divided into the following steps:

1. Scheme Design

The R&D team will determine the appearance, size, driver type, circuit design, acoustic compensation, and other factors based on the data.

Here you need to consider the product's target market, budget, and manufacturing costs.

2. Stocking for Materials

Once the design team has identified all the parts, it's time to start sourcing those parts.

These components may include cabinet materials, drivers, power amplifiers, circuit boards, coils, chips, capacitors, power supplies, etc.

It should be noted that the solutions of each model and different customers of the same model are different, and the required materials also change.

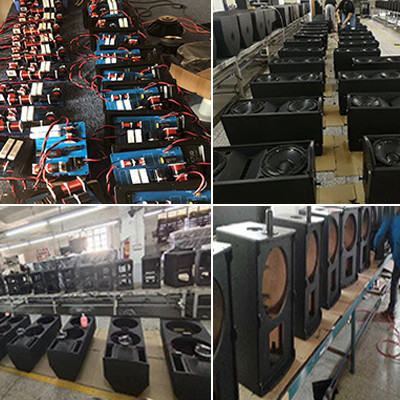

3. Assembly

In the assembly stage, the parts are assembled into a complete loudspeaker.

Assembly includes securing the drive, mounting the circuit board, connecting wires, and assembling the case.

The assembly speed of floor-standing speakers is much slower than that of PA speakers or party speakers because the volume is larger, this increases the difficulty of assembly.

4. Debugging and Testing

Once assembled, tuning and testing are required to ensure the performs to specification.

This includes testing for tuning circuits, acoustic balance, burn-in, and other items.

5. Pack and Store

The last step is to pack and store, then and notify the customer to confirm the delivery date.

The above process is floor-standing speaker production, each part is very important, in order to ensure they are what customers need.